Servo Hydraulic Services

Servo Hydraulic Solutions is a forward-thinking global, highly interactive company that takes pride in our ability to attract and retain a staff of Engineers, technicians, and consultants who innovate solutions to tough problems.

Servo Hydraulic Solutions allows custom design earthquake simulators, vibration testing systems, shake tables and motion platforms. We will not force you into a standard product. We listen to your specific needs and craft a solution to meet those requirements.

No project is too small, no problem is too challenging. We will always arrive at the optimal solution.

- Project Management

- Problem Solving

- Design and Integration Engineering

- Stress Analysis Hydraulic Pumping Systems

- Mechanical Systems

- Electrical Engineering

- Welding engineering Data Acquisition Systems

- Control Systems

- Estimates

- Schematics

- System Manuals Contract Negotiation and Review

- Scheduling

- Project Documentation Communication

- AutoCad Electrical

- Supervision

- Customer Service

High performance, cost effective, scalable hydraulic power supplies.

Servo Hydraulic Solutions’ Open Frame Hydraulic Power supplies are designed for precision control systems, featuring laboratory-grade pumps and micro-clean filtration for long-lasting, low-maintenance operation. Equipped with interlocks for failsafe continuous operation, these units are ideal for centralized systems serving large laboratories or multiple stations, requiring a dedicated pump room to minimize noise.

Robust motor pump units with oversized stainless-steel reservoirs ensure durability and easy servicing. The hydraulic pump, mounted with a bell housing for perfect alignment and replacement facilitation, is driven by a fully enclosed electric motor via a flexible coupling. The system operates at 1800 RPM (60 Hz) or 1500 RPM (50 Hz).

An oversized stainless-steel reservoir with baffling and diffusers allows air dissipation, with a removable top for easy access and cleaning. Hydraulic control components are integrated into a machined manifold block, facilitating the hydraulic interface with various test systems such as earthquake simulators, vibration testing systems, motion platforms, or shake tables.

180 gpm

HPS

Channel

controller

Custom pump

controls

Hydrostatoc bearing actuator, and voice coil servo valve

Submersible

motorpump

180 gpm pump controls

HPS – Hydraulic Power Supply

Actuator and Load Cell

Old Actuators

Servo Control Panel

Working with Site Techs

Remote Pump Control

Electric Actuator

Actuator Servo Controller

Hydraulic Pump Controls

Servo Motor Controls

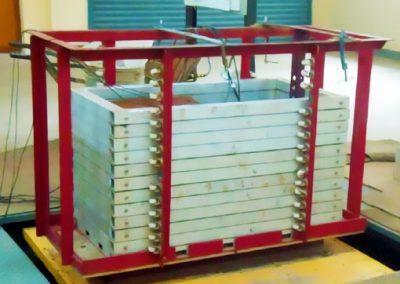

Soil Box

Special Areas of Expertise

We frequently encounter underused or unused lab equipment post large experiments. Our engineers specialize in revitalizing existing equipment, breathing new life into it and exploring innovative uses that were previously overlooked.

Lab Design & Layout of Large Scale Testing Labs

SHS provides dynamic testing systems and also designs and constructs entire testing laboratories. These include such components as strong floors and walls, flat and pit foundations, control rooms, pump rooms, overhead cranes, lab buildings, information technology, and similar infrastructure. Contact SHS to discuss custom laboratory designs to meet your testing needs.Up Grading Existing Servo Hydraulic Equipment

Customers often wonder how to optimize their equipment’s performance. A practical solution is to consult with our experts in your lab. Unlike others constrained by proprietary products or costly upgrades, we advocate for using Commercial Off-The-Shelf (COTS) parts whenever possible. This approach offers flexibility and cost control, providing solutions that others may not offer.Re-habilitation of Un-used Servo Hydraulic Equipment

Customers often wonder what to do with older equipment. A practical solution is to consult with our experts in your lab. Unlike others constrained by proprietary products or policies against reviving older equipment, we believe in maximizing the use of well-maintained assets. We prioritize using Commercial Off-The-Shelf (COTS) parts, offering flexibility and cost control for tailored solutions.Maintenance of Servo Hydraulic Equipment

While many companies provide maintenance plans for testing systems, costs can be steep, and they often limit options to their own parts. Due to our smaller size and commitment to Commercial Off-The-Shelf (COTS) principles, we typically offer comparable services at about half the cost. Additionally, we provide recommendations for optimal conditions.Doug knows what he is doing. He has great technical skills in hydraulic actuators,

controlling system, and data acquisition. Doug did a great job for us building new

actuators for quasi-static testing.

Dr. Mashal

Idaho State University